In this article we're going to take a closer look at strength, ductility and toughness - three very important material properties. Strength is a measure of the stress a material can withstand. Two different values are typically used to define the strength of a material - the ultimate strength and the yield strength. Let's define them by taking a look at the stress-strain curve obtained from a tensile test. The ultimate tensile strength of material is defined as the maximum stress which is reached during the tensile test, corresponding to this point on the stress-strain curve. It is the maximum stress the material can withstand during a tensile test. The yield strength is defined as the stress at which a material begins to deform plastically. Stressing a material beyond its yield strength will result in permanent deformation after the load is removed. Many structures and components are designed to ensure that they only deform elastically. This makes the yield strength a commonly used criterion for defining failure in engineering design codes.

It is possible for failure to occur at stress levels well below the yield strength if the applied load varies with time. This failure mode is called fatigue and I will cover it in a separate article. For some materials the transition from elastic to plastic deformation is not clearly defined. In these cases the yield strength can be defined using the 0.2% offset method. This involves drawing a line with the slope equal to Young's modulus and shifting it 0.2% to the right on the stress-strain curve. So far we have only discussed strengths in the tensile direction. But what about the compressive direction? For ductile materials like mild steel the yield and ultimate strengths are very similar in the tensile and the compressive directions. Tensile tests are usually easier to carry out than compression tests, and so compression tests aren't often performed for these materials.

For brittle materials like concrete and ceramics however, the material strength is much larger in compression than intension. I will talk about why this is the case later on in the article first let's look at some examples of strength values for a few different materials. Tensile yield strengths are shown for ductile materials and ultimate compressive strengths are shown for brittle materials. Graphene is the strongest material to have ever been tested. It is a two dimensional material made up of a single layer of carbon atoms arranged in a hexagonal lattice and linked by strong covalent bonds. Defect-free graphene has an ultimate tensile strength of up to 130 GPa or 19,000 ksi. I've mentioned material ductility a few times in this article so now is probably a good time to define it properly. Ductility is a measure of the ability of a material to deform plastically before fracture.

Let's return to our stress-strain curve. Materials which undergo large amounts of plastic deformation before they break are called ductile materials. These materials fracture at very large strains. Mild steel and gold are examples of very ductile materials. Materials which fracture at very low strains with little to no plastic deformation are said to be brittle. Glass and ceramics like porcelain are examples of brittle materials. Because they don't deform plastically the concept of yield strength is irrelevant for brittle materials. There is no defined transition point between ductile and brittle behavior. Typically a material which has a strain at fracture of less than 5% is considered to be brittle. Now that we have covered what ductile and brittle materials are, let's return to the question of why brittle materials are much stronger in compression than in tension. There are two factors at play. The first factor is that tensile loads tend to encourage the formation and propagation of cracks, whereas compressive loads do not, as illustrated here.

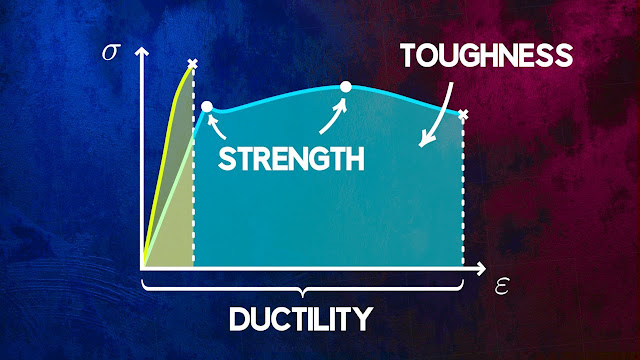

The second factor is that in brittle materials very little or no plastic deformation occurs to redistribute stresses at existing flaws. This means that large stress concentrations build up at the crack-tip, resulting in fracture In ductile materials plastic deformation occurs which relieves these localized stresses. Ductility can be dependent on temperature. A lot of different types of steel for example are ductile at room temperature but become brittle when the temperature drops to below the ductile to brittle transition temperature. This transition temperature is an important design consideration, because ductile failure is normally preferred to brittle failure. One very famous example of brittle failure is the Titanic. The icy waters of the North Atlantic are thought to have caused the steel of the ship's hull to drop below its ductile to brittle transition temperature, resulting in catastrophic brittle fracture. Toughness is the ability of a material to absorb energy up to fracture. It can be calculated as the area under the stress-strain curve. If the area under the stress-strain curve is large, the material will have high toughness, and so will be able to absorb a large amount of energy before fracturing.

For a material to have high toughness is should have a good balance of both ductility and strength. Low strength materials and brittle materials tend to have low toughness. A related property is resilience, which is the ability of a material to absorb energy when deforming elastically. It corresponds to the area under the stress-strain curve but only within the elastic region. Materials with high resilience are will suited for applications where plastic deformation is to be avoided. To summarize, the yield strength of a material defines the stress at which it begins to deform plastically. The ultimate tensile strength defines the maximum stress which is reached during the tensile test. Ductility is a measure of the ability of a material to deform plastically. Toughness is a measure of the ability of a material to absorb energy up until fracture, and resilience is a measure of the ability of a material to absorb energy while deforming elastically.

That's it for now. If you enjoyed reading the article please remember to subscribe for email notifications and don't forget to comment down below and keep visiting for more articles like this!

0 Comments

If you have any doubts, Please let me know